Data Analytics for Reliability and Integrity Management (RIM)

New reactor designs are focused on risk-informed processes to support all stages of development (design, licensing, operation, and retirement).

Some of these processes are well-known since they are used for light-water reactors; however, the safety classification of systems, structures,

and components (SSCs), development of performance requirements, and application of special treatments are unfamiliar to light-water reactors.

More specifically, developing and monitoringperformance requirements are a completely new problem. An industry initiative led by the American Society

of Mechanical Engineers has been in development for a few years—requirements for a reliability and integrity management (RIM) program for nuclear

power plants. The objective is todefine, evaluate, and implement strategies to ensure that SSC performance requirements are defined,achieved, and

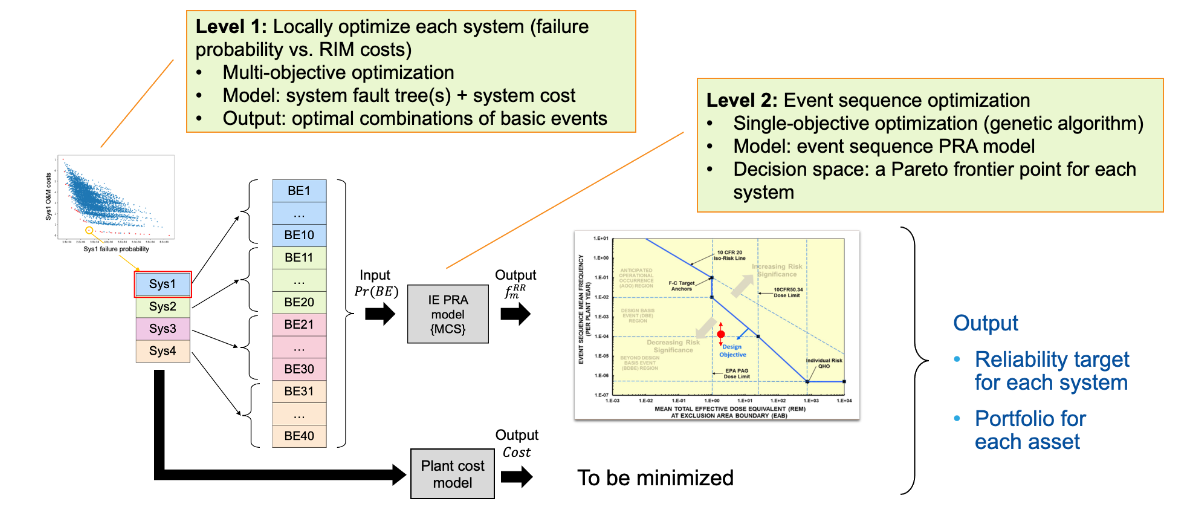

maintained throughout the plant lifetime. This paper provides an overview of the data analytics methods designed to support the RIM program for

advanced reactors, and it targets two research directions: SSC reliability target allocations and RIM strategy identification and evaluation.

These methods are applied to specific case studies. These analyses present various possibilities andoptions for meeting RIM program requirements,

including considerations of a tradeoff between reliability and economics and design option optimization.

The concepts of structures, systems and component (SSC) failure rate and failure probability are in principle used to model the occurrence of events (such as SSC failure) that are considered stochastic in nature. This modeling choice is imposed by the fact that we do not possess enough knowledge to model such an event (or the phenomena causing such an event) in deterministic terms through either data- or physics-based considerations. The deployment of advanced surveillance, monitoring, and prognostic and health management systems in many industries is very helpful to system engineers and plant operators monitoring the health of SSCs. These systems provide deterministic indications about SSC health and performance; consequently, the occurrence of an SSC failure event cannot be considered completely stochastic in nature. Given these premises: does it make sense to think in terms of SSC failure rate and failure probability when monitoring and surveillance activities are performed? This paper answers this question by first identifying the links between SSC health, performance, and reliability through a system engineering point of view. We then proceed by identifying the deterministic and stochastic elements of the ensemble “SSC and monitoring/surveillance” system. Based on these considerations, the SSC failure rate or failure probability is modeled by considering only the stochastic elements of the ensemble “SSC and monitoring/surveillance” system.

The Intertwining of Data, Decisions, and Reliability