Plant Health Management (PHM)

Industry Equipment Reliability (ER) programs are an essential element that

support safe and economic plant operations. The effectiveness of these programs

is addressed in several industry-wide and regulatory programs. However, as

currently implemented, these programs are labour intensive and expensive. There is

an acute industry need to leverage advanced monitoring technology (including

pattern recognition, diagnostics, and prognostics) to reduce costs and improve

engineering effectiveness. Although the use of advanced monitoring has been

successfully implemented to assess equipment and system performance in a

number of industries (e.g., commercial and military aviation, transportation, gas

turbine electrical generation), these technologies have not penetrated extensively

into the commercial nuclear power sector. As a result, deployment of these

technologies has the potential to provide significant improvements in the

performance of critical Structures, Systems and Components (SSCs) (e.g., via

detection and diagnosis of degraded performance at an incipient stage) and reduce

costs associated with monitoring and regulatory compliance.

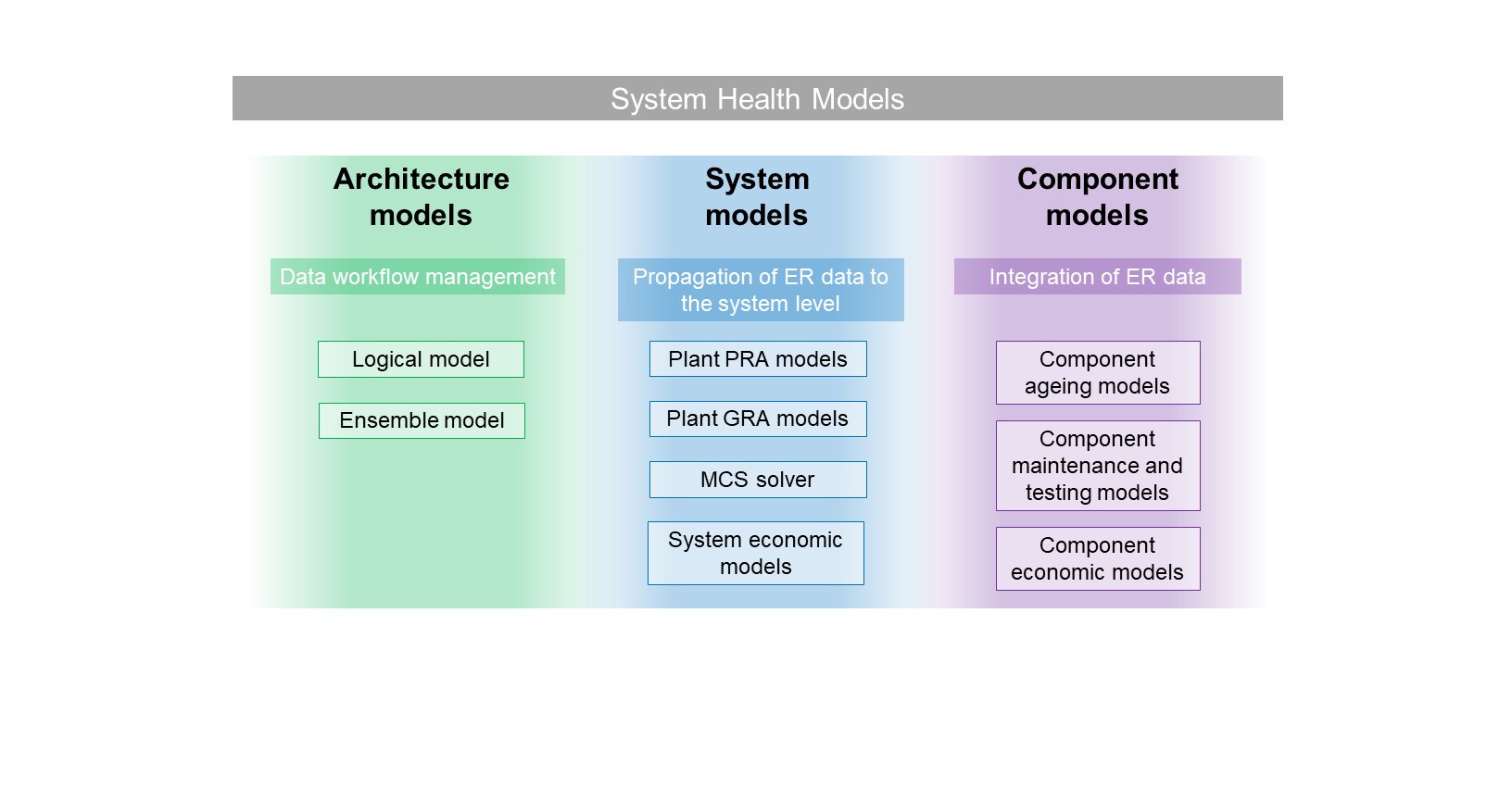

The objective of this project is to leverage advanced computational capabilities

to support enhanced system performance and health management. A fundamental

objective of this effort is to integrate various elements of system health monitoring,

management, and reporting in a manner that is significantly less labour intensive

and is at least as technically effective as current programs. This will be

accomplished by integrating various elements of system health monitoring,

management. The final goal is to

manage equipment and system performance and its financial risk and reduce costs

associated with monitoring and regulatory compliance.

The first application of this project targets the integration of risk-informed

applications with the plant system health program. The goals are essentially the

following: 1) apply innovative data analytics methods to assess component/system

health, and, 2) link the system health program with risk models. These goals are

designed to target the fact that the U.S. commercial nuclear power industry is

aggressively pursuing implementation of several risk-informed applications to

reduce regulatory burden and operating costs. These applications include

Alternative Treatments (10CFR50.69) and Risk-Managed Technical

Specifications (TSTF-505). To obtain maximum value from these applications,

their execution must be strongly integrated with a robust and automated System

Health program. While typically plant risk models focus only on the safety aspects

of the plant, we are extending plant risk models to include the economic plant risk.

The overall outcome of this work will be a framework that will apply plant

health data to provide actual risk (both safety and economic) information that can

support more informed and effective decision-making. Risk-informed applications

are linked to this analysis framework by identifying their direct impact on plant

risk models. The foreseen outcomes of this framework are: 1) the reduction of

nuclear power plant owner resources to manage equipment reliability, and, 2) the

ability to provide, in real time, assessments of the safety and economical risks

associated with plant equipment as plant configuration changes.

RIAM and PHM projects overview

Reports

D. Mandelli, Z. Ma, R. Youngblood, S. St Germain, C. Smith, P. Talbot, S. Hess, D. Dube, C. Pope, J. Miller, M. Robbins, D. Das, M. Azarian, J. Coble

Plant Integral Risk-informed System Health Program

Tech. Rep.INL-EXT-19-55808, Idaho National Laboratory (INL), 2019

D. Mandelli, C. Wang, J. Cogliati, C. Smith, S. Hess, R. Sugrue, C. Pope, J. Miller, S. Ercanbrack, D. Cole, J. Yurko

Integration of Data Analytics with Plant System Health Program

Tech. Rep. INL/EXT-20-59928, Idaho National Laboratory (INL), 2020

Models overview