RISMC: Risk Informed Safety Margin Characterization

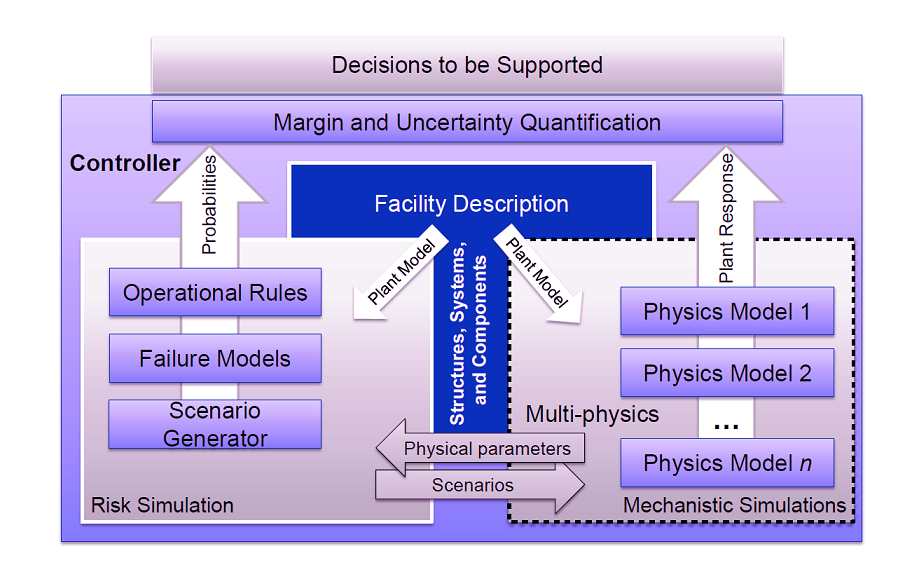

Safety is central to the design, licensing, operation, and economics of nuclear power plants (NPPs). As the current light water reactor (LWR) NPPs age beyond 60 years, there are possibilities for increased frequency of system structure and component (SSC) failures that initiate safety-significant events, reduce existing accident mitigation capabilities, or create new failure modes. Plant designers commonly “over-design” portions of NPPs and provide robustness in the form of redundant and diverse engineered safety features to ensure that, even in the case of well-beyond design basis scenarios, public health and safety will be protected with a very high degree of assurance. This form of defense-in-depth is a reasoned response to uncertainties and is often referred to generically as “safety margin.” Historically, specific safety margin provisions have been formulated, primarily based on “engineering judgement”. The ability to better characterize and quantify safety margin holds the key to improved decision making about LWR design, operation, and plant life extension. In a sense, contemplation of LWR operation beyond 60 years does represent a kind of “extended design basis” operation. A systematic approach to characterization of safety margins represents a vital input to the licensee and regulatory analysis and decision making that will be involved. In addition, as R&D in the LWR Sustainability Program and other collaborative efforts yield new data and improved scientific understanding of physical processes that govern the ageing and degradation of plant SSCs (and concurrently support technological advances in nuclear reactor fuels and plant instrumentation and control systems) needs and opportunities to better optimize plant safety and performance will become known. To successfully understand safety margins, the Risk Informed Safety Margins Characterization (RISMC) Pathway will clearly define and demonstrate the safety margin approach. The determination of the degree of a safety margin requires an understanding of risk-based scenarios. Within a scenario, an integration of plant behaviour (i.e., operational rules such as technical specifications, operator behaviour, and SSC status) and associated uncertainty will be required to interface with a systems code. Then, to characterize safety margin for a specific performance metric of consideration (e.g., peak clad temperature), the integrated plant simulation will determine time and scenario-dependent outcomes for both the load and capacity. Specifically, the safety margin approach will use the physics-based plant results (the “load”) and contrast these to the capacity (for the associated performance metric) to determine if safety margins have been exceeded (or not) for a family of accident scenarios.

|

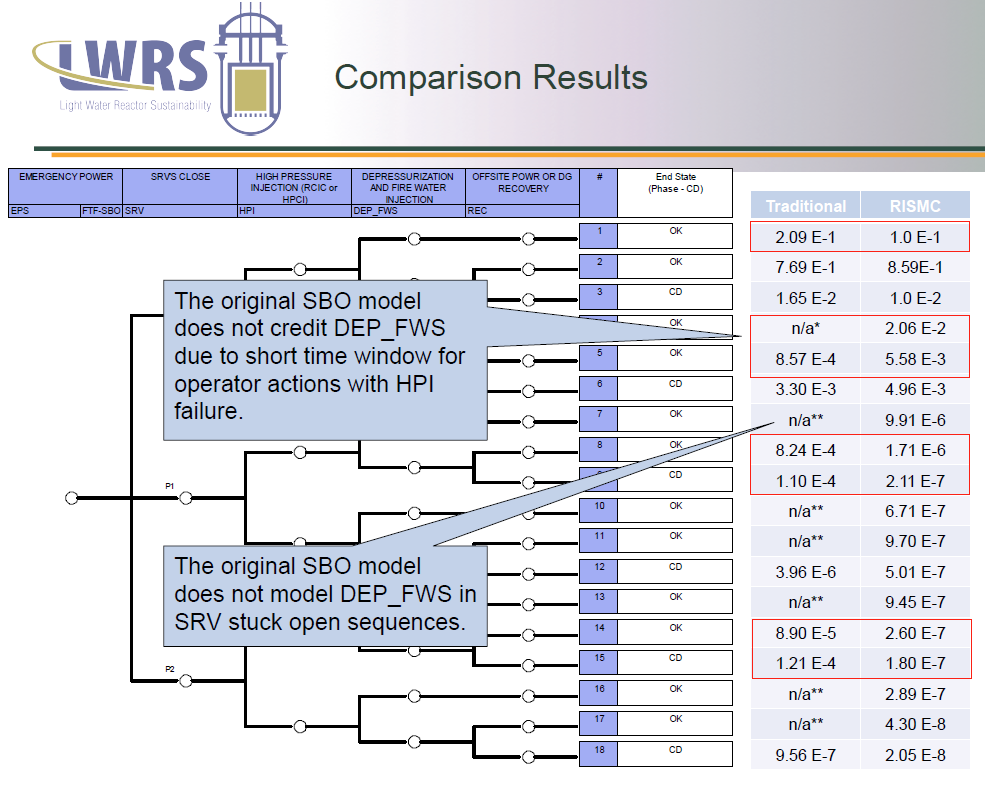

Support and modeling for the boiling water reactor station black out case study using RELAP and RAVEN Tech. Rep. INL/EXT-13-30203, Idaho National Laboratory (INL), 2013 |

|

Risk-Informed Safety Margin Characterization Methods Development Work Tech. Rep. INL/EXT-14-33191, Idaho National Laboratory (INL), 2014 |

|

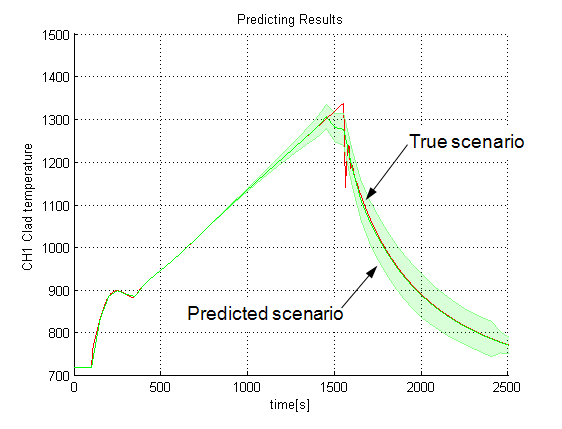

Improved Sampling Algorithms in the Risk-Informed Safety Margin Characterization Toolkit Tech. Rep. INL/EXT-15-35933, Idaho National Laboratory (INL), 2014 D. Mandelli, C. Smith, A. Alfonsi, C. Rabiti, J. Cogliati, H. Zhao, I. Rinaldi, D. Maljovec, P.Talbot, B. Wang, V. Pascucci Reduced Order Model Implementation in the Risk-Informed Safety Margin Characterization Toolkit Tech. Rep. INL/EXT-15-35933, Idaho National Laboratory (INL), 2014 |

|

Data Analysis Approaches for the Risk-Informed Safety Margins Characterization Toolkit Tech. Rep. INL/EXT-16-39851, Idaho National Laboratory (INL), 2014 |

|

Integration of Human Reliability Analysis Models into the Simulation-Based Framework for the Risk-Informed Safety Margin Characterization Toolkit Tech. Rep. INL/EXT-16-39015, Idaho National Laboratory (INL), 2014 |

|

Dynamic PRA Modeling of a Multi-Unit Power Plant INL/LTD-17-42398 D. Mandelli, C. Parisi, A. Alfonsi, D. Maljovec, S. St Germain, R. Boring, S. Ewing, C. Smith, C. Rabiti DYNAMIC PRA OF A MULTI-UNIT PLANT Probabilistic Safety Assessment (PSA) Conference 2017 |

|

MEASURING RISK IMPORTANCE IN A DYNAMIC PRA FRAMEWORK Probabilistic Safety Assessment (PSA) Conference 2017 D. Mandelli, C. Parisi, Z. Ma, D. Maljovec, A. Alfonsi, C. Smith Risk-Informed Analysis of Commercial Nuclear Reactors: the RISMC Approach and 10CFR50.69 INL/LTD-17-43208 |

|

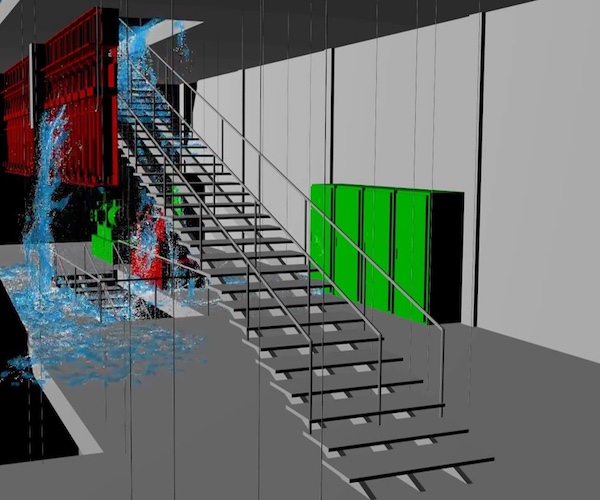

Analysis of pressurized water reactor station blackout caused by external flooding using the RISMC toolkit Tech. Rep. INL/EXT-14-32906, Idaho National Laboratory (INL), 2014 |