AI/ML for Equipment Reliability

The past two decades have seen the emergence of advanced prognostic and health management

computational tools for anomaly detection, diagnostic, and prognostic purposes, which are helping

system engineers and plant operators monitor the performance of several assets and optimize plant

resources (personnel, time, and money). In the same direction, nuclear power plants (NPPs) are now in

the process of digitizing operation and maintenance activities to track trends and events at the system or

plant level (e.g., plant planned shutdown or system taken out of service) and, more importantly, observed

abnormal conditions. In this respect, NPPs generate large amounts of equipment reliability (ER) data, which

record the historic performance of a large number of components and assets. As a drawback, engineers and

operators are now facing the challenge of processing the amount of ER data being continuously generated,

which is not only extremely large but also appears in both textual and numeric forms.

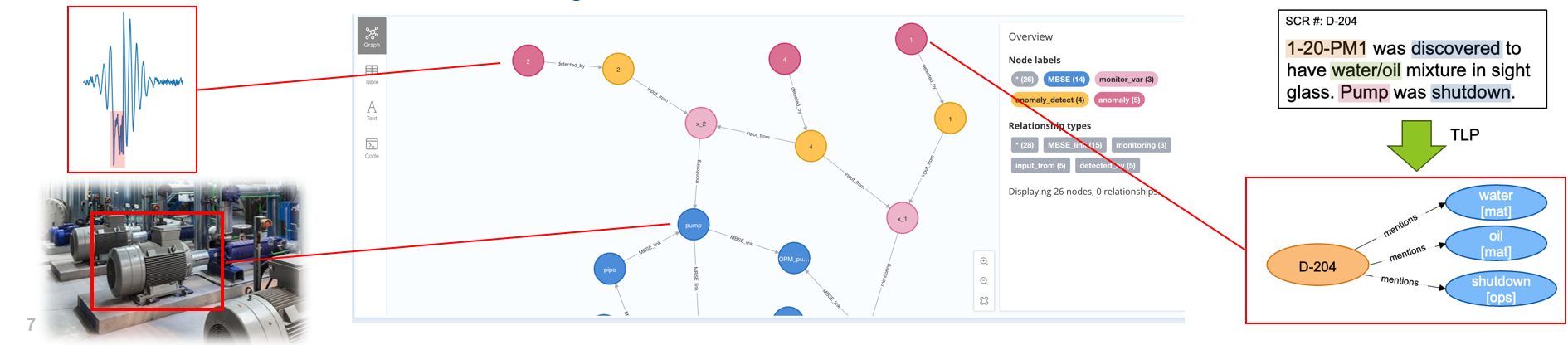

This project directly tackles this challenge by providing computational methods to assist system engineers

and operators with the means to extract knowledge from ER data. Our approach deviates substantially from

state-of-practice methods where the main focus is almost exclusively on numeric data analysis. Instead, we

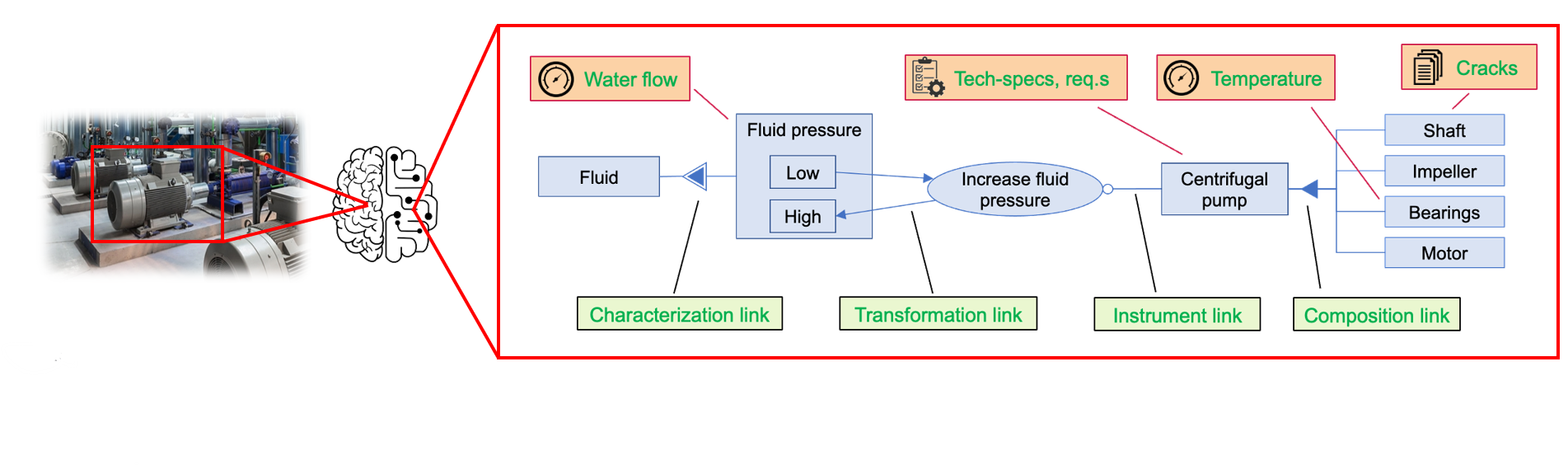

employ a model-based system engineering (MBSE) model approach to represent systems and assets to

capture their architectural and functional (i.e., cause-effect) relations. Textual and numeric ER data

elements are processed by identifying first which elements of the developed MBSE elements they are

referring to. For numeric ER data, this task is fairly easy provided there are system design documents that

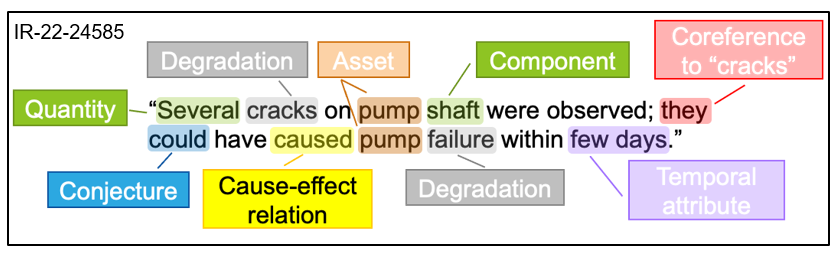

indicate a precise association between asset and monitored time series. On the other hand, this task is more

challenging when dealing with textual data; we employ technical language processing (TLP) methods to

“extract knowledge” from textual elements.

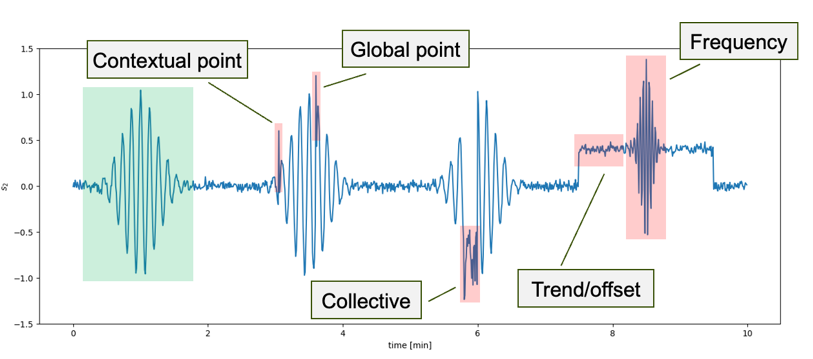

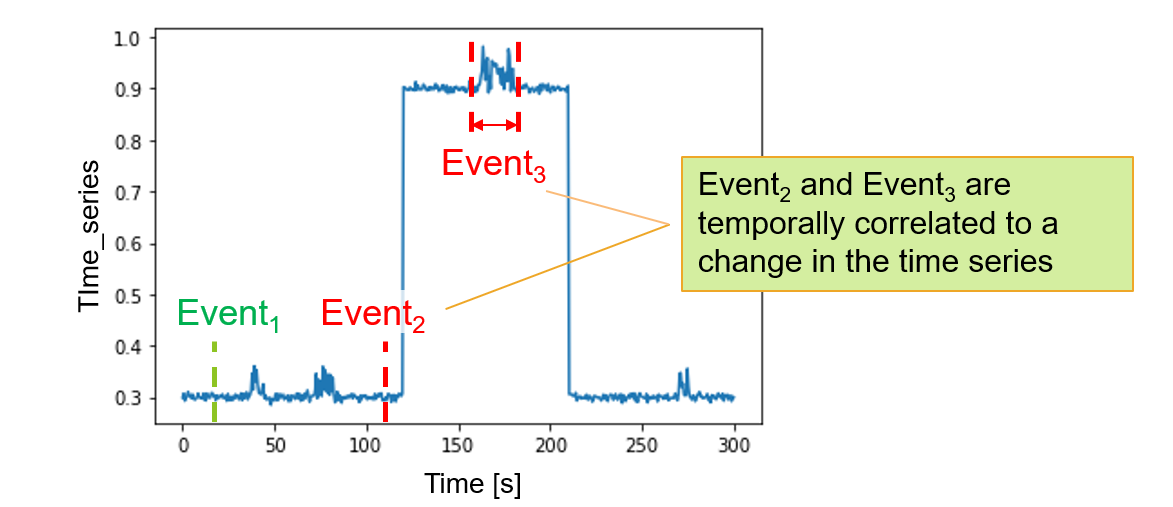

Filtering abnormal behaviors can then be performed on numeric data through anomaly detections methods

and textual elements (by understanding their semantic nature). Such abnormal instances that are associated

with a specific MBSE element are then stored in a relational database. This database takes the form of a

graph where the main skeleton is the actual system MBSE model and abnormal instances are “linked” to

the skeleton. At this point, both numeric and textual data elements are integrated and put into context. From

here, graph-based analysis methods can be employed to perform “machine reasoning,” including

identifying abnormal patterns and the root cause behind them.

The presented methods have been developed in the digital analytics, causal knowledge acquisition and

reasoning (DACKAR) repository.

MBSE system and equipment representation

Matrix profile for anomaly detection

Knowledge extractioon from textual data

Event causality

System architectura and data knowledge graph